Publications IPH Magazine Revista IPH Nº18 Floor covering of hospital floors: Case study of the vinyl blanket applied in a hospital in Salvador, BA

- IPH Magazine Nº18

- The therapeutic garden

- Hospital Sul América and the modern design in health architecture

- RECOMMENDATIONS FOR PLANNING AND CARRYING OUT RENOVATION WORKS IN FUNCTIONAL HOSPITALS

- How spatial syntax can help mitigate the effect of future pandemics in Brazil

- A reflection on the impact of the Covid-19 pandemic on architecture and urbanism

- Floor covering of hospital floors: Case study of the vinyl blanket applied in a hospital in Salvador, BA

Floor covering of hospital floors: Case study of the vinyl blanket applied in a hospital in Salvador, BA

Bruna Pereira Magalhães

Abstract

The vinyl blanket is a type of floor covering composed of polyvinyl chloride (PVC) that has been widely used in hospital environments for offering low cost, different sizes and colors, easy applicability, and maintenance. The aim of this article was to analyze the application of vinyl blanket in the largest public hospital in the North and Northeast, located in the city of Salvador, Bahia, in order to improve its application in these environments. This analysis was developed through a case study in a specific sector of the hospital, Hemodynamics. The study was developed through research in articles already published about the hospital sector and its standards, in addition to the process of installing the vinyl blanket to better understand the object and the material to be studied. Based on the knowledge acquired, the study was developed with on-site verification method of application of the vinyl blanket and the evaluation of the result regarding the physical and hygienic requirements

for a hospital.

Keywords: Vinyl blanket, hospital floor covering, hemodynamic.

1 INTRODUCTION

Floor coverings are of great importance for any development, as they can provide comfort to the user, as well as finishing and functionality for the environments. However, it is necessary to make a careful study about its use, since it is necessary to worry about the technical performance of the coating: durability, safety, cleaning, appearance, acoustics, and maintenance.

In hospital environments, the vinyl blanket has been widely used due to its ease of application, maintenance and cleaning, in addition to the cost-benefit. In addition, this coating meets the normative requirements described in the Resolution of the National Health Surveillance Agency, Collegiate Board Resolution No. 50/2002 (RDC).

This article aims to value the quality of the application of the vinyl blanket and analyze whether or not it meets the physical and sanitary requirements of a hospital environment.

The hospital under study, inaugurated in the late 1980s, is the largest in the North and Northeast regions of Brazil. With more than 600 beds, it serves120,000 people in outpatient clinics per month and 1,300 hospitalizations, in addition to performing 3,500 deliveries per year, becoming a reference in areas such as obstetrics, pediatrics, physiotherapy and orthopedics, as well as procedures of great complexity, such as neurosurgery (INTS, 2019).

The present study was first developed from a bibliographic research, with the objective of knowing the standards and specifications of a hospital environment and the vinyl blanket in order to analyze the applicability of the coating. Thus, some visits were made on site, in order to monitor and analyze the installation of the material and, therefore, to investigate the conditions of hygienic and physical efficiency of a vinyl blanket in the hospital. This study, in addition to addressing technical aspects, stands out in its social character, since it aims to improve the application of this coating in compliance with all functional and sanitary needs of a hospital, aiming at reducing the risks of hospital infection.

2 FLOOR COVERINGS

2.1 General concepts

In a hospital environment, the choice of floor covering is established by the functionality of the institution, which, according to RDC no. 50/2002 of the National Health Surveillance Agency (2002, p. 36), is understood as "[...] the physically determined and specialized space for the development of a given activity, characterized by differentiated dimensions and facilities".

The environments of a hospital, according to RDC No. 50/2002 of the National Health SurveillanceAgency, are classified according to the transmissibility of diseases by the following criteria:

Critical areas - are environments where there is an increased risk of transmission of infection, where risk procedures are performed, with or without patients, or where immunosuppressed patients are found;Semi-critical areas - are all compartments occupied by patients with infectious diseases of low transmissibility and non-infectious diseases;Non-critical areas - are all other compartments of healthcare facilities not occupied by patients, where no risky procedures are performed (BRASIL, 2002, p. 99).

The environments, according to RDC No. 50/2002 of the National Health Surveillance Agency (2002, p. 92), should follow the "[...] hygrothermal and luminous comfort requirements, which in the location of the building on the ground must be followed the requirements of the local work code". With this, it is necessary to observe the functionality of the place from the characteristics of the population system that uses it and the devices and equipment present.

In this sense, the materials for coatings in these hospital environments, according to RDC No. 50/2002 of the National Health Surveillance Agency (2002, p. 107), should be "[...] resistant to washing and the use of disinfectants [...]". In addition, this choice has to prioritize "[...] finishing materials that make surfaces monolithic, with as few grooves or gaps as possible, even after frequent use and cleaning [...]"

(BRAZIL, 2002, p. 107).

For the footers, according to RDC No. 50/2002 of the National Health Surveillance Agency (2002, p. 107), it is important to look at their union "[...] with the wall so that the two are aligned, avoiding the traditional footer bounce that allows the accumulation of dust and it is difficult to clean." Thus, for this junction, according to RDC No. 50/2002, it is noticed that:

The execution of the junction between the footer and the floor must be in such a way that it allows the complete cleaning of the formed corner. Baseboards with sharp rounding, besides being difficult to perform or even unsuitable for various types of materials used for finishing floors, because they do not allow rounding, do not facilitate the cleaning process of the site, whether done by waxers, or by squeegees or brooms wrapped by cloths (BRASIL, 2002, p. 107).

Finally, another important feature in the choice of coating is low sound emission, since noise, both for professionals and for the sick, can "[...] cause disorders to these people and even influence patient recovery" (GOES, 2010, p. 17).

2.2 Types

According to Sayegh (2007), with the wide variety of types of floor coverings on the market, it is necessary to have doubled attention in choosing the best product to apply in the desired environment. Therefore, the responsible professional should evaluate the material regarding hospital requirements, especially sanitary, with attention to its cleaning and maintenance.

In this sense, according to Bicalho and Barcellos (2002, p. 63-64), the commonly used and available materials have the following characteristics:

- Industrial high strength - monolithic floor (floor junction and continuous baseboard), molded on site, based on stone dust, which allows integrity of the joints to the floor;

- Synthetic resin coating based on epoxy - monolithic floor, executed on top of a concrete base on which it becomes resistant and easy to clean;

- Vinyl on plates - easy installation and cleaning (with damp cloth, without using a lot of water);

- Vinyl or linoleum in blankets - easy installation and cleaning, intact (welded joints), which makes it monolithic (continuous footer execution);

- Granite - due to its porosity, it becomes a very resistant floor, especially for heavy traffic, with characteristic of "hiding" dirt;

- Ceramics - low water absorption index, has several types that go up to high resistance to traffic and impacts. A good example is the porcelain type (hard, practically waterproof, but of high cost). It is important to choose the type that has a narrow joint and the use of epoxy-based grout;

- Marble - characteristics similar to granite, with less resistance and more absorption. It is indicated to use it in the most polished form to facilitate its cleaning;

- Conductive - used to eliminate electrostatic charges in certain environments with high risk of explosion and thermal shock, due to the presence of certain substances. Therefore, it is important to have the grounding of the equipment and runoff of the floor to the land potential.

2.3 Vinyl blanket

Vinyl floors, according to Sayegh (2007), "are formed by apolyvinyl chloride (PVC) compound mixed with specific additives that confer malleability and resistance. They are available in plates and blankets." With this, according to the author, for hospital environments:

"the blankets, with widths between 0.6 m and 2 m, are ideal for places where cleaning is essential, because they form a monolithic set, which includes the skirting board. By not presenting seams, it avoids dust accumulation, cleaning condition required for hospital facilities and laboratories" (SAYEGH, 2007, online).

Despite the great applicability of the vinyl blanket in hospital environments, Sayegh (2007, online) recalls that [...] "most of the floors available on the market are recommended only for internal use, as they lose color with exposure to the sun and do not resist rain and constant water, which cause their detachment". In this same sense, the manufacturer Tarkett warns that "[...] excessive use of water in cleaning floors with dry joints can cause the floor to depart from the floor, making room for infiltrations" (TARKETT, 2016, p.6).

The maintenance of the vinyl blanket is another positive feature in this type of coating, because, according to Sayegh (2007), one can easily "[...] replace damaged parts without affecting the rest of the coating", which implies simple maintenance. In addition, according to the author, the vinyl blanket is very useful for hospital environments, because it has acoustic absorption capacity for the emission of sound from carts with polyurethane wheels (SAYEGH, 2007).

2.4 Application

2.4.1 Preparation of the floor

For Sayegh (2007, online) "[...] the success of the floor system still depends on a good preparation of the floor and correct application of the material, with mortars and grouts specific to each product".

In this sense, the types of counter floors allowed for the application of the blanket, according to the General Installation Manual of the manufacturer TARKETT (2016, p. 8), are:

- Cement - concrete slab or plucked;

- Ceramic - has joints less than 5 mm;

- Stone - polished granites and marbles. The parts must be adhered and leveled with joints less than 5 mm;

- High strength floor;

- Paviflex - allowed if it is with only another layer of the Paviflex type. These plates must not have malfunctions, they must be intact, firm, with acrylic adhesive and without wax. If there is any trace of this wax, it should be removed, and the surface regularized to start the installation;

- Locations with heating systems;

- On mezzanine.

On the other hand, some counter floors are not allowed, according to the General Installation Manual of the manufacturer TARKETT (2016, p. 8-9), among them:

- Burnt cement - the floor should be cut and a new base should be prepared;

- Wood (laminates, clubs, parquets, boards, etc.) - removal and preparation of a new base;

- Stones and ceramics with joints larger than 5 mm - removal and preparation of a new base;

- Paviflex with bituminous adhesive, called "black glue" - complete removal of the floor and glue. The glue remnant should be sanded with wet sand and with the aid of an electric sander and diamond disc. Without this procedure, the coating installed on top may take off;

- Other vinyl floors (LVT, blankets) - removal and preparation of a new base;

- Acrylic or epoxy paint - the floor should be sanded with sandpaper no. 60 or electric sander to create porosity;

- Industrial kitchen;

- Outdoor.

2.4.2 Cleaning of the counter floor

According to the General Installation Manual of the manufacturer TARKETT (2016), for the application of the blanket, it is necessary to remove all dust from the floor to apply the bonding adhesive of the vinyl coating.

2.4.3 Vinyl blanket glue

The application of the adhesive, according to the manufacturer TARKETT (2016), should be done in circular movements with the use of a clipper and, to minimize the effects of the teeth of the plucking, a roll of wool should be used.

After applying the adhesive, the manufacturer TARKETT (2016, p. 15) suggests that the blanket be glued smoothing "[...] the coating with a wooden ruler coated with carpet [...]" and then use "[...] the 50 kg steamroller in order to avoid airbubbles."

For splicing one blanket into another, the manufacturer TARKETT (2016, p.15) recommends that: "[...] the joints must be tightly closed, touching each other's ends, without being compressed or tooopen"; and be used "[...] hot welding on vinyl blankets in all commercial areas to prevent water used during cleaning from penetrating the backfloor, wall or under the blanket." As for the hospital environment, the manufacturer recalls that the "[...] facilities in health areas should always have hot welding", in addition to the "[...] hot welding [be] mandatory in patches of blankets and conductive plates" (TARKETT, 2016, p. 16).

2.4.4 Baseboard

For curved baseboards, according to the General Installation Manual of the manufacturer TARKETT (2016, p. 14), it is recommended to "[...] leave a leftover of the blanket on the edges near the walls and according to the size of the baseboard provided in the project." With this, this manual advises the use of a curved support, because "[...] facilitates floor maintenance and ensures excellent hygiene" (TARKETT, 2016, p. 18). Also according to this manufacturer, for the execution of the baseboard glue, it issuggested that "[...] acrylic adhesive should be applied with low-coat wool roller and double contact: on the wall and on the coating" (TARKETT, 2016, p. 12).

To give finishing, the manufacturer also suggests sealing the "[...] silicone trims, using a professional applicator to avoid excess" (TARKETT, 2016, p. 20).

2.4.5 Post-application care

In post-application care, the manufacturer TARKETT (2016) recommends the removal of all powder from the vinyl blanket after its installation and the protection of the floor with the help of the person responsible for the work to avoid damage to the product already installed.

3 THE HOSPITAL

The hospital under study stands out for being the largest public hospital in the North and Northeast of the country, inaugurated in the 80's, with emphasis on procedures of great complexity. In this way, it can serve more than 30,000 people in the outpatient clinic, has more than 600 beds, 1,300 inpatients per month, and perform more than 3,500 deliveries per year. In this sense, it has become a reference in several areas, such as emergency services, general surgery, oral maxillofacial, pediatric and neonatal, medical clinic, pediatrics, digestive hemorrhage, high-risk maternity and, mainly, neurosurgery (INTS, 2019).

Among the various areas, the Hemodynamics sector of the hospital underwent a renovation of requalification and expansion of services, with the objective of serving a greater number of patients and adapting to the means of work. Thus, Hemodynamics is a sector that, according to Linch, Guido and Fantin (2010, p. 489):

[...] medical specialties such as cardiology, radiology, neurology, among others, use Hemodynamics Units (UHDs) as support for the performance of diagnostic or interventional therapeutic procedures. These make use of methods sometimes faster and more accurate, with techniques aimed at lower risks to patients (LINCH; GUIDO; FANTIN, 2010, p. 489).

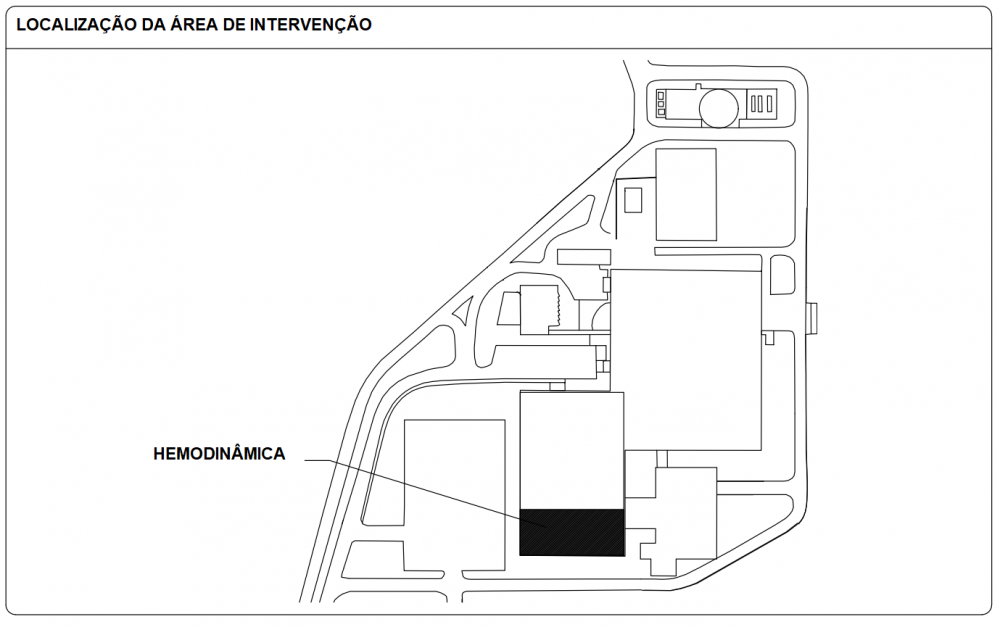

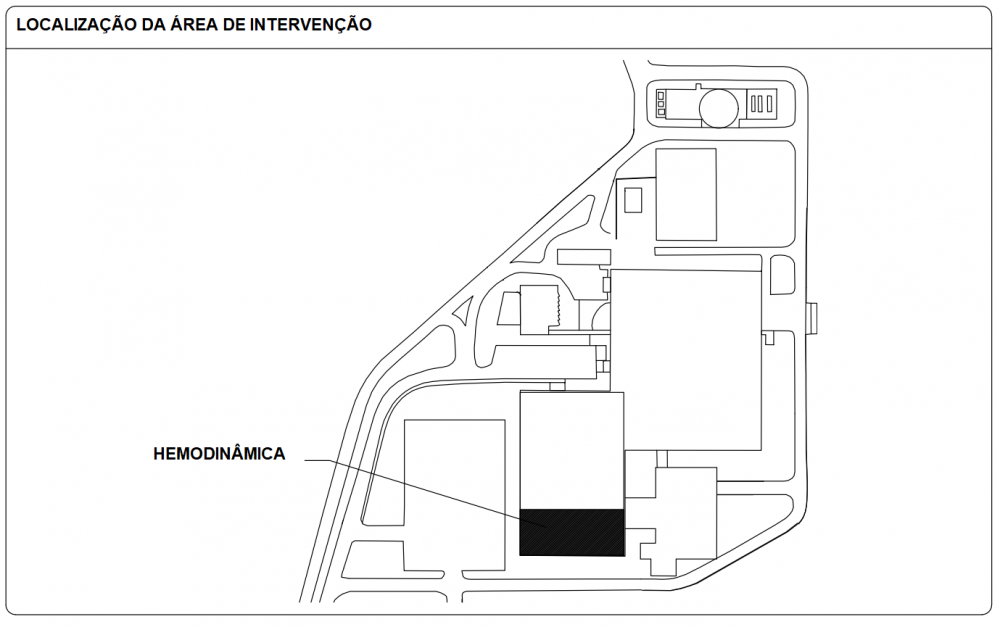

Located on the Ground Floor, from Block B of the main building, Hemodynamics was remodeled in order to humanize the unit, adapt it according to the appropriate methodology to the work processes and the standards that cover it, in addition to expanding its services in the hospital. The location of this sector can be seen in Illustration 1.

Illustration 1: Hemodynamics Location Plant Source: Own Authorship (2017)

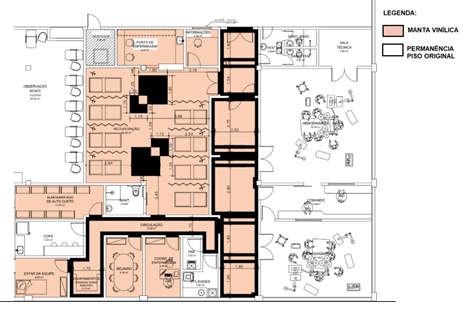

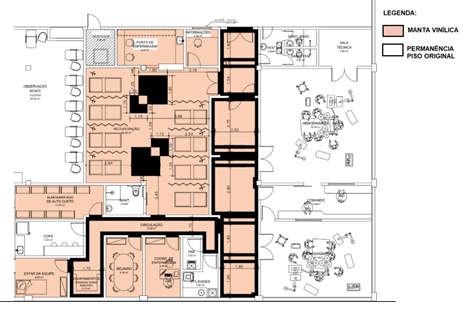

The recovered area was 343 m², whose space was already used for UHD. The expansion includes the implementation of a new examination room and support environments, examination recovery room, nursing station, coordinations, meeting room, team living room and warehouse, as can be seen in Illustration 2.

Illustration 2: Ampliation and vinyl blanket layout

Source: Own Authorship (2017)

Among all the modifications made, we highlight the installation of the high traffic vinyl blanket in much of Hemodynamics (in pink). The blanket, which has characteristics of being distributed in rolls of 20 m x 2 m with 2 mm thickness, antifungal and antibacterial, was installed following the paging plant with patterns and colors defined by design, broken down in Illustration 2. It is noteworthy that there was no installation of this coating in humid areas (canopy, toilets, utilities, and Department of Cleaning Material), since it does not resist well to constant water.

4 CASE STUDY TO EVALUATE THE APPLICATION OF THE VINYL BLANKET IN A HOSPITAL IN SALVADOR

4.1 Research methodology

The case study was conducted, first, with literature research on the theme treated; then daily visits were made for observation and analysis of the application of the vinyl blanket in loco. This follow-up of the service was carried out with the completion of a work diary and photographic reports, with the objective of recording the main events of the remodeling for approximately four months.

Despite being a practical service with fast application, its installation required time, due to concern with the integrity of the coating. This concern begins with the proper and thorough execution of the floor (essential step for the application of the vinyl blanket). Then, brickwork, coatings, installations, finishes were performed and, only after four months of intervention, the installation of the vinyl blanket was carried out.

This whole process is related to the concern of avoiding any damage to the vinyl blanket with subsequent activity (movement of people, material and objects). In this way, only after the execution of the services of closing and opening walls, painting, electrical installations, and ceramic laying, the vinyl blanket can be installed.

4.2 Analysis of the application of the vinyl blanket

4.2.1 Counter floor

As a fundamental part for the good performance of the vinyl blanket, the execution of the floor was done with caution and with the objective of regularizing the areas that were damaged with the total removal of the old vinyl coating, the Paviflex (product produced from the base of soybean oil) with bituminous adhesive. The removal of the Paviflex was indispensable, because the vinyl blanket installed over this surface could come out in the future, as warned by manufacturer.

4.2.2 Cleaning of the counter floor

The complete cleaning of the remaining dust of the floor was done so that the glue adhesive had greater support to the blanket and the floor, as recommended by the manufacturer. This service can be seen in Illustration 3.

Illustration 3: Removal of dirt from the floor for the application of the vinyl blanket

Source: Own authorship (2017)

After cleaning the floor, it was possible to observe traces of the black glue from the old coating, the Paviflex, still very present on the floor, as can be seen in Illustration 3. Therefore, it was necessary to remove it with a helicopter-type concrete straightener to sand the glue with damp sand, completely removing it.

4.2.3 Vinyl blanket glue

The glue adhesive was applied and spread on the blanket and the floor. In circular movements and with the aid of the toothed plucking, the glue was spread and, later, the wool roller was used to minimize the markings of the plucking, as suggested by the manufacturer. After applying the adhesive, the blanket was positioned, distributed and pressed against the floor to secure it throughout the area. Its distribution followed the specifications contained in the detailing plant, in the colors and defined patterns. In regions of junction between blankets, milling on the seams and welding with hot welding were performed to amend them and make them uniform, as shown in Illustration 4.

Illustration 4: Installation of the vinyl blanket

Source: Own authorship 2017

4.2.4 Baseboard

The baseboard was executed in a curved manner. For this, a leftover of the blanket was left near the walls, as suggested by the manufacturer. With this, the double contact adhesive was spread on the baseboard and in the region of the wall to be installed. To help, a curved support was used to facilitate the execution of the curvature of the footer. Then a silicone glue was applied above the skirting board to completely seal the vinyl blanket and make it fully uniform, giving the finish to the coating. Details in Illustration 5.

Illustration 5: Details of the baseboard and the silicone glue

Source: Own authorship 2017

4.2.5 Post-application care

After installation, the vinyl blanket was cleaned, removing all the dust generated by the application. However, it was not protected from the activities that were performed on site after installation.

4.3 Result

Evaluating the results of the aplication of the vinyl blanket, it is observed that this floor covering was able to meet the physical and hygienic requirements of the hospital for the Hemodynamics sector, due to a good installation of the coating.

As for the physical requirements, the vinyl blanket brought safety, hygrothermal, luminous and visual comfort due to the layout of the coating, the color design and comfortable patterns. In addition, the blanket provides a large acoustic capacity, with reduced noise of stretchers, chairs and people moving in and out of the unit.

As for hygienic requirements, the floor became uniform and monolithic (reducing the possibility of water infiltration) from good executions of seams between the blankets and curved baseboards, in addition to the counter floor itself. In addition, the type of baseboard adopted provides a complete cleaning of the accumulation of dirt in the corners and wall encounters, facilitating the cleaning of the place; necessary for hospital facilities and laboratories, reducing the risk of infections.

Post-installation care was not fully taken, in contrast to the good application of vinyl blanket in Hemodynamics. Although the floor was cleaned of impurities caused by its application, no protection was made. Finishing activities to Hemodynamics, such as the application of plots on the windows and walls, installation of counter tops and furniture, in addition to the movement of people, were performed without the adequate protection of the vinyl blanket, such as plastic canvases.

5 FINAL CONSIDERATIONS

Vinyl flooring has become a coating widely used in hospital environments due to its practicality of installation; variety of sizes, colors and models; facility of cleaning; and simple maintenance.

In view of the advantages of using the vinyl blanket in the remodeling of the Hemodynamics department in Salvador Public Hospital, the designer's sensitivity to use such a coating stands out, corresponding to the physical and immunological requirements for the site, mainly because it meets the requirements of RDC No. 50/2002. Physically, the coating brought acoustic and luminous comfort to patients and staff. As for hygiene, the coating has become uniform and monolithic, protecting the space from infections, and facilitating its cleaning, respectively.

In this sense, changes, and remodeling in hospital environments, particularly in floor coverings, should start, first, from the technical capacity of the professional and his/her knowledge regarding the needs of a hospital in compliance with physical, logistical and, mainly, hygienic requirements, through ANVISA RDC No. 50/2002, so as not to harm the entire system to combat hospital infection.

The good result of the application was possible due to the good execution of the floor. Since this is the basis of the whole process, in addition to having been well regularized and leveled, the manufacturer's recommendations regarding the removal of glue remnants from old coatings, in this case Paviflex, were met. Thus, it was possible to guarantee the integrity and durability of the blanket, avoiding future detachments.

With regard to post-installation care, the protection of the vinyl blanket immediately after its application is indispensable, since any damage can harm all its integrity and investment, causing rework on site.

Finally, cleaning hospital environments is essential to avoid contamination and infections. However, it is important to note that the vinyl blanket is not water resistant. In this way, it is important to take care when cleaning the coating.

REFERENCES

BICALHO, Flávio de Castro; BARCELLOS, Regina Maria Gonçalves. Materiais de Acabamento em Estabelecimentos Assistenciais de Saúde. In: CARVALHO, A.P.A. (Org.). Temas de Arquitetura de Estabelecimentos Assistenciais de Saúde. Faculdade de Arquitetura. Universidade Federal da Bahia, Salvador, 2002. Available at <http://bvsms.saude.gov.br/bvs/publicacoes/temas_arquitetura_estabelecimentos_assistenciais_saude2.pdf>. Access on Apr 2, 2018.

BRASIL. Ministério da Saúde. Agência Nacional de Vigilância Sanitária. Resolução da Diretoria Colegiada 50, de 21 de fevereiro. Apresenta: regulamento técnico para planejamento, programação, elaboração e avaliação de projetos físicos de estabelecimentos assistenciais de saúde. Brasília, 2002.

FIORENTINI, Domingos Marcos Flávio; LIMA, Vera Helena de Almeida; KARMAN, Jarbas B. Arquitetura na prevenção de infecção hospitalar. Brasília, 1995. Available at <http://www.anvisa.gov.br/servicosaude/manuais/infeccao.pdf>. Access on Apr 2, 2018.

GOES, Wagner Martins. Subsídios para escolha de materiais de acabamento de estabelecimentos assistenciais de saúde - um estudo de caso do Hospital Regional do Mato Grosso do Sul. Salvador, 2010. Available at <https://geahosp.files.wordpress.com/2015/05/goes-wagner-martins-materiais-eas20101.pdf>. Access on Apr 2, 2018.

INTS (INSTITUTO NACIONAL DE TECNOLOGIA E SAÚDE). Relatório de Atividades Consolidadas - 10 anos. [s.l.].: INTS, 2019. Available at http://ints.org.br/wp-content/uploads/2020/01/Book_relatorio_atividades_INTS_10-ANOS_Digital.pdf. Access on Oct 5, 2021.

LINCH, Graciele Fernanda da Costa; GUIDO, Laura de Azevedo; FANTIN, Simone de Souza. Enfermeiros de unidades de hemodinâmica do Rio Grande do Sul: Perfil e satisfação profissional. Contexto Enferm, Florianópolis, v. 3, n. 19, p. 488-495, jul. 2010. Available at <http://www.scielo.br/pdf/tce/v19n3/a10v19n3.pdf>. Access on May 7, 2018.

SAYEGH, Simone. Revestimento certo: propriedades mecânicas, instalação e manutenção - conheça esse e outros critérios para especificação de pisos. Revista Téchne: a revista do engenheiro civil, São Paulo, Pini, n. 126, set. 2007. Available at <http http://techne17.pini.com.br/engenharia-civil/126/artigo287471-1.aspx >. Access on Apr 2, 2018.

SOARES, Tanísia Negrello. Revestimentos de pisos hospitalares: avaliação das condições de uso em Porto Alegre. Porto Alegre, 2009. Available at <http://www.lume.ufrgs.br/bitstream/handle/10183/24125/000741862.pdf?...1>. Access on Apr 2, 2018.

TARKETT. Manual geral de instalação. Jacareí, SP, fev., 2016. Available on <http://tarkett.com.br/midias/downloads/14576114711.pdf>. Access on Apr 10, 2018.

Send by e-mail: